Notes on Invisible Wood

By Richard Howe

So much of the public face of Manhattan — the walls of its streets — is brick or stone that it is often an effort to remember that behind a great many of the older masonry exteriors is an interior built almost entirely of wood. Even the famous brownstones are for the most part brick and wood structures faced with stone. Some 80 percent of the nearly 150,000 buildings that were put up on the island in its “long” 19th century, 1790–1910, were of what came to be called “ordinary” construction: load-bearing exterior walls of brick supporting an interior structure of timber joists, wooden floors, wooden rafters supporting wood-sheathed roofs, wood-framed interior partitions, wooden furring and laths, wooden staircases, interior and exterior doors, doorway and window frames, and a whole miscellany of wooden moldings and other fittings.

19th century “ordinary” brick and wood construction standing cheek by jowl at the northwest corner of First Avenue and 9th Street in the East Village. Behind the brick facades the interior structures are built of wood. (Photo: Author)

Though as many as 20,000 of these buildings are still standing — the estimate is very crude — none of this wood is visible from the street except for the exterior doorways and window frames. Equally invisible, though hidden by the losses of time rather than by masonry, are 19th century New York’s 30,000-odd wood frame houses and other all-wood buildings, no more than a handful of which are still standing. Wood was one of the two most common building materials in New York — the other was brick — for the better part of 300 years; it was overtaken by steel and concrete only in the 20th century, and even then only where the size of new buildings—in particular, their height—exceeded what was structurally feasible or cost-effective with wood. The history of New York as a material artifact is in no small part a history of its use of wood as a building material.

In the century and a half from the arrival of the first settlers to the start of the War of Independence, the inhabitants of Nieuw Amsterdam / New York may have put up as many as 5,000 buildings, of which perhaps 1,000 were demolished or burnt along the way; about 4,000 were standing in the city prior to the great fire of 1776. The number of buildings increased more or less in proportion to the growing population, with ten or fewer built per year on average up to the 1660s and a hundred or more per year in the 1770s — a significant increase, but not enough to overly stress the supply of lumber. The later buildings may have used some 20,000 board feet of lumber apiece (a board foot is a volume of wood equivalent to a board one foot wide, one foot long, and an inch thick, i.e., 144 cubic inches or one-twelfth of a cubic foot): a hundred such buildings would have been equivalent to the lumber product of about 100 acres of forest. Though the edges of the forest were rapidly receding under the onslaught of the huge demand for fuelwood — the island of Manhattan was 80 percent deforested by the middle of the 18th century at the latest — the Hudson River provided a relatively inexpensive means of transporting wood in quantity to the city, and there was always still more forest waiting for the axe. Annual demand for lumber in colonial New York was relatively modest in relation to supply, amounting to only a small fraction of the demand for fuelwood. Supplying the city with lumber was just enough of a problem to support an equally modest commercial traffic in it.

This situation changed after the War of Independence. From 1790 to its peak around 1910, the population of New York — Manhattan after 1898 — increased 70-fold, from about 33,000 to about 2,232,000. The 150,000 or so buildings that went up on the island to accommodate this growth—more than a third of them replacements for older buildings or buildings lost to fire—consumed several tens of billions of bricks and some five to six billion board feet of lumber, equivalent to the product of some 400–500 square miles of forest. New building starts averaged about 1,000 a year prior to the Civil War and were above 2,000 in 17 of the post-war years, with peak years approaching and surpassing the 3,000 mark. Something on the order of 120,000 of these buildings were ordinary brick and wood construction of modest size: 20–25 feet wide and 50–80 feet deep on their 20–25 × 100 foot lots, and 50–70 feet high (four to six stories); the average was about 22.5 × 70 × 60 feet and consumed something on the order of 40,000 board feet of lumber. Most of the remaining 30,000 were smaller wood framed buildings that consumed on average perhaps 20,000 board feet. Construction at this pace would have stressed the 18th century lumber supply infrastructure far beyond the breaking point, all the more so as the growing population of the wider New York metropolitan region represented a demand for lumber at least twice that of Manhattan’s. In 1890, just past the peak of the great 1880s building boom, the area that in 1898 would become Greater New York imported over 1.3 billion board feet of lumber, nearly 5 percent of the total U.S. lumber production in that year.

Trees are not an industrial product, yet paradoxically it was the new industrial technologies of the 19th century that made it possible to meet the demand for lumber posed by the growth of New York and to continue building a substantially wooden city well into the 20th. As the nation’s appetite for fuelwood — the volume of which far outstripped what was cut for lumber—pushed the edge of the forest further and further away from the city, transportation costs for both fuelwood and lumber rose: the city was already importing wood by the end of the 17th century and in the 18th century faced frequent shortages and high prices, despite the economies of rafting logs down the Hudson River and the establishment of some 200 water-wheel powered sawmills in the region. But by the middle of the 19th century, even the now more than 3,000 such mills along the upper Hudson River and its tributaries — most of them small operations, equipped with only a single-saw — were not enough to keep up with the demand by what was by then the largest lumber market in the world. By the 1840s New York was importing timber from as far away as Michigan, Wisconsin, and even Minnesota, and only the transition to steam-powered sawmills, ships, river boats, and railroads made it economically feasible to continue exploiting these distant sources of supply.

Log pond and piling ground by the river in upstate New York in the 19th century. Here river rafting and railroads combined to keep abreast of New York’s insatiable demand for lumber. (Photo: Library of Congress)

Despite the new industrial technologies, lumber prices rose: wholesale lumber prices (inflation adjusted) more than doubled between 1790 and 1850, but distances to the sources had increased by as much as a factor of ten, from mostly under a hundred miles to as much as a thousand miles, and prices would more than double again by 1910, as an ever larger proportion of the city’s lumber was brought in — by rail, by rivers and canals, by coastal waterways — from the more distant rather than the more local sources. But the city’s rapidly expanding economy easily absorbed the price increases, and rising prices were not enough to slow the pace of building. It is fair to say that without the industrialization of wood’s supply infrastructure, New York could not have grown anything as rapidly as it did in the 19th century.

Supply was not the only problem to be overcome by the new industrial technologies. There was also the difficulty of joining pieces of lumber to one another. Although nails, the most common fastener for this purpose today, are as old as civilization itself — the oldest specimens date from more than 5,000 years ago — until the 18th century they were made one at a time, and were correspondingly expensive, so much so that it was not uncommon to burn an abandoned building simply to recover its nails. So-called cut or “square” nails, sheared from iron bars or plates, were introduced in the mid-18th century, along with machines to assist in the shearing, but the nail-making process was not fully mechanized until the 1820s. Wire nails were first made in the early 1850s, but the now ubiquitous and inexpensive steel wire nail only began to come into widespread use in the 1880s, by which time the Bessemer converter and the Siemens open hearth furnace had made steel and steel products into a major industry that could supply the wire from which nails could now be made cheaply in hitherto unimaginable quantities: in the 28 years 1872–1899, the total U.S. production of nails increased nearly two and a half times, while the production of cut nails dropped by half, i.e., the production of steel wire nails in 1899 was nearly double the production of cut nails in 1872.

Gangs of steam-powered and belt-driven machines for making “square” cut nails made it possible for 19th century nail-makers to keep pace with America’s constantly rising demand for nails; they were eventually displaced by machines for making steel wire nails, which had much higher output. (Photo: Library of Congress)

Wholesale nail prices (inflation adjusted) dropped about 30 percent from 1800 to 1820, as more and better nail-making machines came into use. The full mechanization of cut nail-making in the 1820s brought the price down a further 30 percent by 1830, where it remained — albeit with ups and downs that followed the vicissitudes of the economy — until the 1870s. By 1910 the steel wire nail had brought the wholesale price of nails down to less than 20 percent of what it had been in 1800, though cut nails still accounted for roughly 20 percent of all nails manufactured. These decreasing prices correspond to a radical increase in the production of nails, which reached nearly a half a million tons per year by 1900 — about 500 (!) times the amount produced in 1790 and 10 times as much as what had been the entire production of iron for all uses in the United States in 1810. Without this enormous increase in the supply of nails, and the concomitant if by no means equal price declines, it would have surely been impossible to put up nearly 150,000 wood-framed and ordinary brick and wood buildings on the island of Manhattan in the span of 120 years, to say nothing of the millions of such buildings that went up all over America in the 19th century.

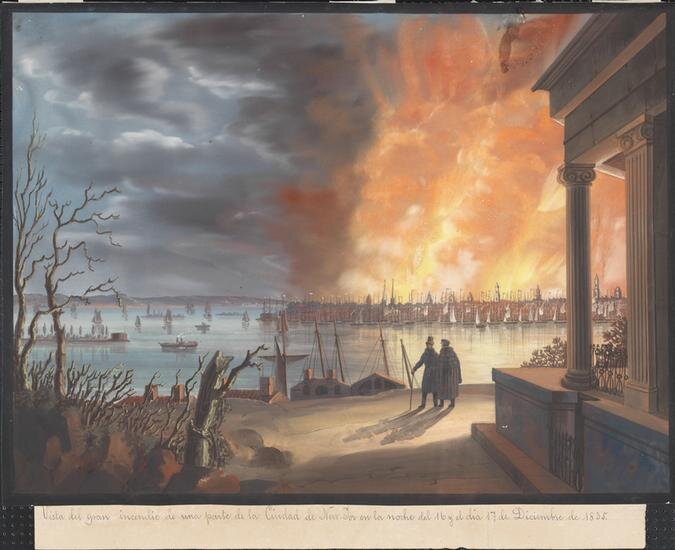

Steam and steel, the 19th century’s major industrial technologies, enabled the lumber industry to keep up with rising demand, albeit at a rising cost, and brought the price of nails down dramatically. But they were unable to overcome wood’s chief drawback as a building material, particularly in a dense urban environment: wood burns. Fire in the city has its own history, but that history has been closely interwoven with the city’s use of wood as a building material from the very beginning. The first recorded conflagration in Nieuw Amsterdam was reported in 1626; another was mentioned in 1628, which may have been the same one—Stokes thought it was. The long succession of fire-prevention and fire-fighting measures, including the use of fire-engines imported from London starting in 1731, testifies to the extent to which 17th and 18th century New York was built of wood, as do the “disastrous” fires — Stokes’ category — of 1757, 1770, and 1772, culminating in the Great Fire of 1776, which may have destroyed as much as a fourth of the city.

Contemporary lithograph showing the ruins of the 1835 Great Fire in New York as seen from Exchange Place. The fire destroyed some 700 buildings downtown (image: New York Public Library)

Lewis Taffien, Fire, 1835 (Image: Museum of the City of New York)

American New York after the War of Independence was equally flammable: the great fire of 1835, which destroyed 700 buildings, is well-known, as is the great fire of 1845, which destroyed 300; but there were tens of thousands of lesser fires in the course of the century — probably at least 50,000 (the estimate is conservative) — most of them relatively minor, damaging only a part of a building, but some of which consumed many buildings and even whole blocks at a time—Stokes lists another 32 “disastrous” 19th century fires in addition to the so-called “great” ones. Despite the dangers inherent in the use of wood as a building material — which led to the series of city ordinances requiring fire-escapes, starting in 1860 — in 1912 there were still over 82,000 buildings of ordinary brick and wood construction standing on the island and nearly 7,000 wood-frame buildings. Even then there were only about 3,000 fireproof buildings in Manhattan, most of them too large to use wood as a structural material; many of them were iron or even steel framed. Ordinary construction continued to dominate: in 1914 only 43 percent of the 426 new building plans filed for Manhattan were to be fireproof structures, the remaining 57 percent were still to be ordinary construction with its high — and highly flammable — wood content. Even today the number of fires in the city can astonish: in Manhattan alone there were 468 officially “serious” fires — those with at least four fire units engaged — in 2011 out of a total of 5,762 structural fires.

The structural life span of a building is the span of time before major repairs are needed to ensure against its possible collapse. The economic life of a building, however, is the span of time in which it is a profitable asset, given the costs of ordinary maintenance and the competitive situation in the real estate market. The working assumption in the 19th and early 20th centuries was that the economic life of an ordinary building would be no more than 35–45 years on average, the age at which older buildings had usually been replaced with newer, larger, and perhaps better ones. As a result, it was often not thought necessary to build for a structural life of more than 50–75 years: a building would almost certainly be demolished and replaced before it had a chance to become decrepit. But in the 1920s, when the combination of commuter railroads, bridges, and tunnels, the automobile, and the new and highly restrictive immigration laws resulted for the first time in more people leaving Manhattan than were coming in — from 1920 to 1930 the borough’s resident population declined by over 400,000 — demand for residential space in particular also declined, bringing the economic life of thousands of buildings to an unexpectedly early end and making the continued operation of thousands more only marginally profitable.

A block-long row of 19th century “ordinary” brick and wood buildings on the west side of Second Avenue between 12th and 13th Streets is dwarfed by new high-rises (Photo: Author)

Over the next 50 years Manhattan’s resident population declined by a further 400,000, leaving more and more under-utilized older buildings standing well past the end of their expected structural life span. Despite some 60,000 demolitions since 1910 — only 10,000 of them for “urban renewal,” the majority to make way for the expanding high-rise areas of Midtown, Downtown, and the Upper East and West Sides—some 20,000 of them are still standing and occupied, some of them renovated, most of them not: it is an exceptional block in Manhattan, even in Midtown, that is not graced — or sometimes blighted — by at least one of these buildings. A few of these buildings are isolated holdouts surrounded by newer, larger, and taller buildings, but most of them stand side by side in concentrations that lend a 19th century charm to the island’s residential neighborhoods. But for anyone who has ever lived in one of these older buildings, their unevenly slanting floors, cracked and tilting walls, creaky staircases, and sticking doors and windows are the all too visible signs of the warping, twisting, bowing, and cracking of an invisible and invisibly aging wooden structure. While the brick or stone exteriors of these buildings contribute endlessly to the visual charm of the city, their interior construction is less durable, and the question naturally arises as to whether, having survived their first hundred years, they will be able to survive their second.

Richard Howe is a frequent contributor to the Blotter, and is writing a book about the history of New York as a hand-made artifact. He runs the photographic study New York in Plain Sight: The Manhattan Street Corners.

Further reading

The late Michael Williams’ Americans and their Forests: A Historical Geography (1989) is a virtual encyclopaedia of the uses and abuses of our forests over the past several hundred years.

Between them, John Steven’s Dutch Vernacular Architecture in North America 1640–1840 (2005) and Jeroen van den Hurk’s Imagining New Netherland: Origins and Survival of Netherlandic Architecture in Old New York (dissertation, 2006) provide an in depth view Dutch methods and materials of construction both at home and in the new world.

Joyce Goodfriend’s Before the Melting Pot: Society and Culture in Colonial New York City (1992) covers the transition from Dutch to English architecture and building practices in the generations after the English took over the city in 1664, and Charles Lockwood’s Manhattan Moves Uptown (1976) provides a fine narrative of the northward growth of the city in the 19th century.

The great nineteenth century New York City Clerk David Valentine’s Manuals of the Corporation of the City of New York (1842–1866 & 1868–1870) provide numerous statistics of many kinds related to building in 19th century New York. The Union History Company’s long out of print History of Architecture and the Building Trades of Greater New York (1899) remains an astonishing source of data on just about every aspect of its subject.

The Census Bureau’s Historical Statistics of the United States from Colonial Times to 1970 should be everyone’s first stop in every search for time-series data on almost any aspect of U.S. history. Arthur Harrison Coles’ Wholesale Commodity Prices in the United States, 1700-1861, in particular its Statistical Supplement: Actual Wholesale Prices of Various Commodities is an extraordinary compilation of monthly (!) prices for 46 commodities in six cities—including New York—in the 18th and 19th centuries up to Civil War.

Edward Allen’s professional handbook, Fundamentals of Building Construction Materials and Methods, is invaluable for its expositions of historical as well as contemporary materials and methods.

I. N. Phelps Stokes’ Iconography of Manhattan Island (1915–1928) remains, as usual, indispensable for just about everything.